PREDICTIVE MAINTENANCE SERVICE

The real-time service able to continuously monitor the current status of the plant and perform the real-time failure prediction.

The I-EM’s system PREDICO is able to predict inverter faults status before they actually occur, allowing the customer to take actions to reduce plant under performances.

Key features

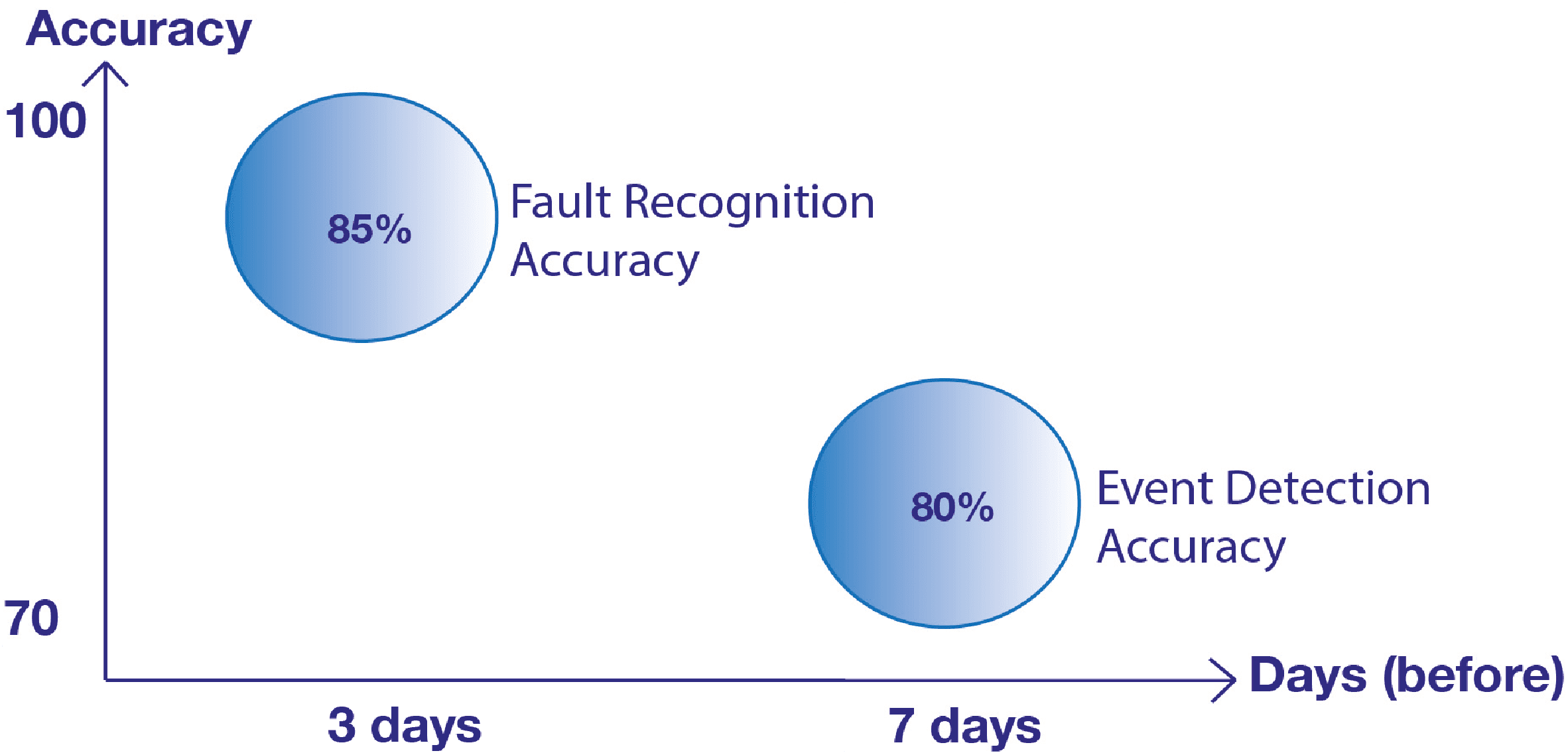

> Event Detection – prediction of inverter deviations from nominal behavior

> Advanced Fault Recognition – prediction of a specific class of faults

Key benefit

> Keep optimal performances of PV plants over time

> Avoid Loss production period

> Allow efficient O&M procedure planning

The i-EM’s predictive maintenance service is based on efficient combination of Advanced Artificial Intelligence algorithms.

Output interface

> Different warning levels (green, yellow, orange and red) corresponding to 4 different inverter fault severities

> Quality Index trend warning time-evolution and corresponding inverter errors

> Fault class and severity of the inverter alarm

> Action-to-solve (if available from inverter manufacturer)

The service is highly customized on customer’s plant characteristic.

> Inverter technology and Plant Configuration represent relevant input of the model ensuring customized solution to customer plant.

> Historical manual and automatic alarms logbook-based models training ensures to follow customers’ plant specific behavior

Performance

The PREDICO Service reliability has been widley assessed through the whole software development cycle as well as during the real-time services to customers.

The performance are continuously assessed by mean of the usual classification metrics such as Sensitivity, Specificity, Accuracy and ROC curve.

i-EM solutions are completely customizable on demand and are provided as Platform as a Service (PaaS)