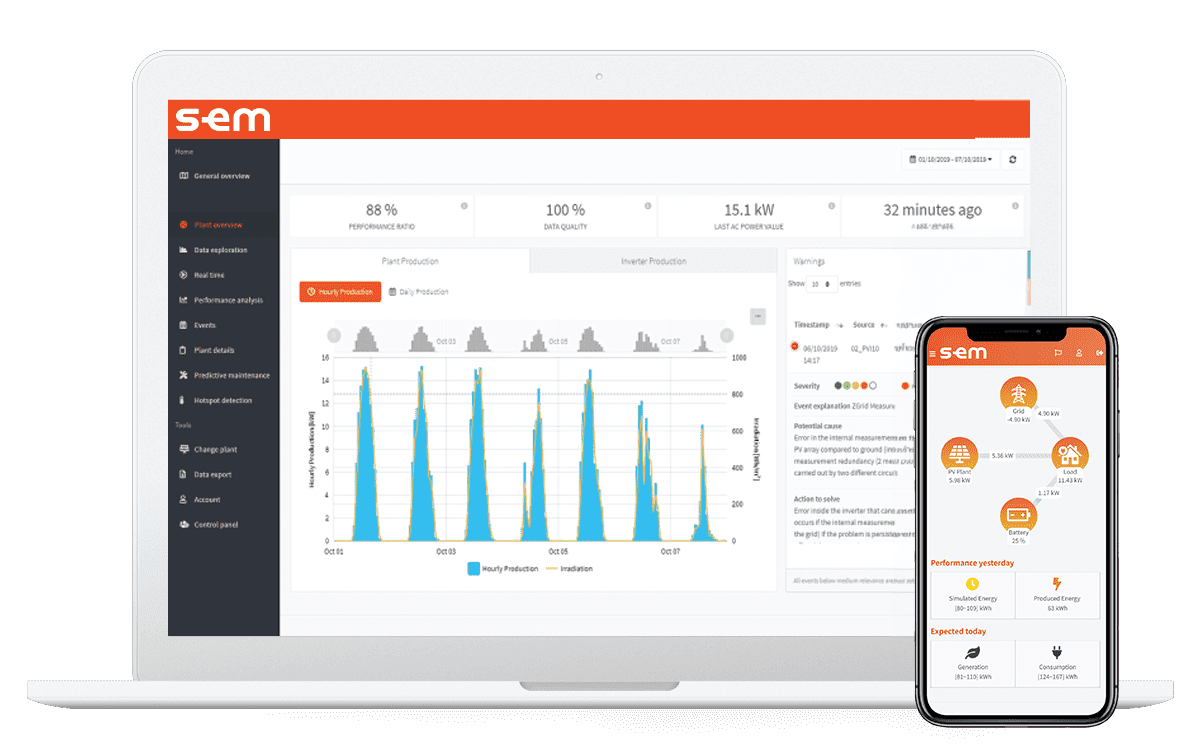

S-EM, the SaaS for the Solar Energy Management, provides real time monitoring and predictive activities for PV installations.

The solution is integrable in any type of plant, user-friendly, and highly intuitive for operators of all levels. S-EM is completely modular, easily adapting to your unique needs.

i-EM is holder of the Solar Monitoring Best Practises Mark, the self-evaluation-based label to promote transparency and excellence in solar monitoring services.

Two packages

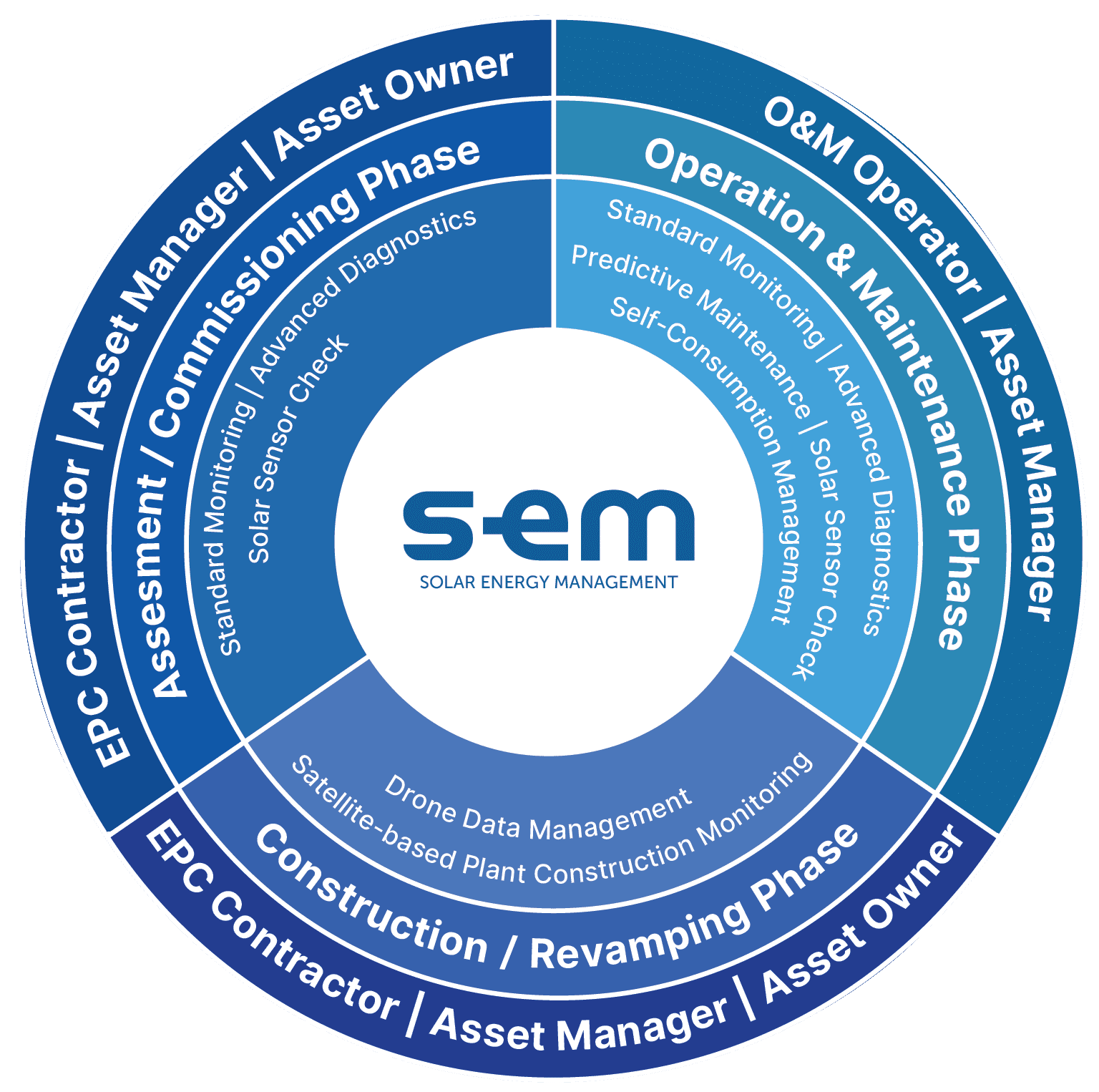

The holistic solar asset life-cycle interoperable solution

S-EM covers the entire solar asset life cycle from construction to the energy yield of photovoltaic installations.

SOLUTION

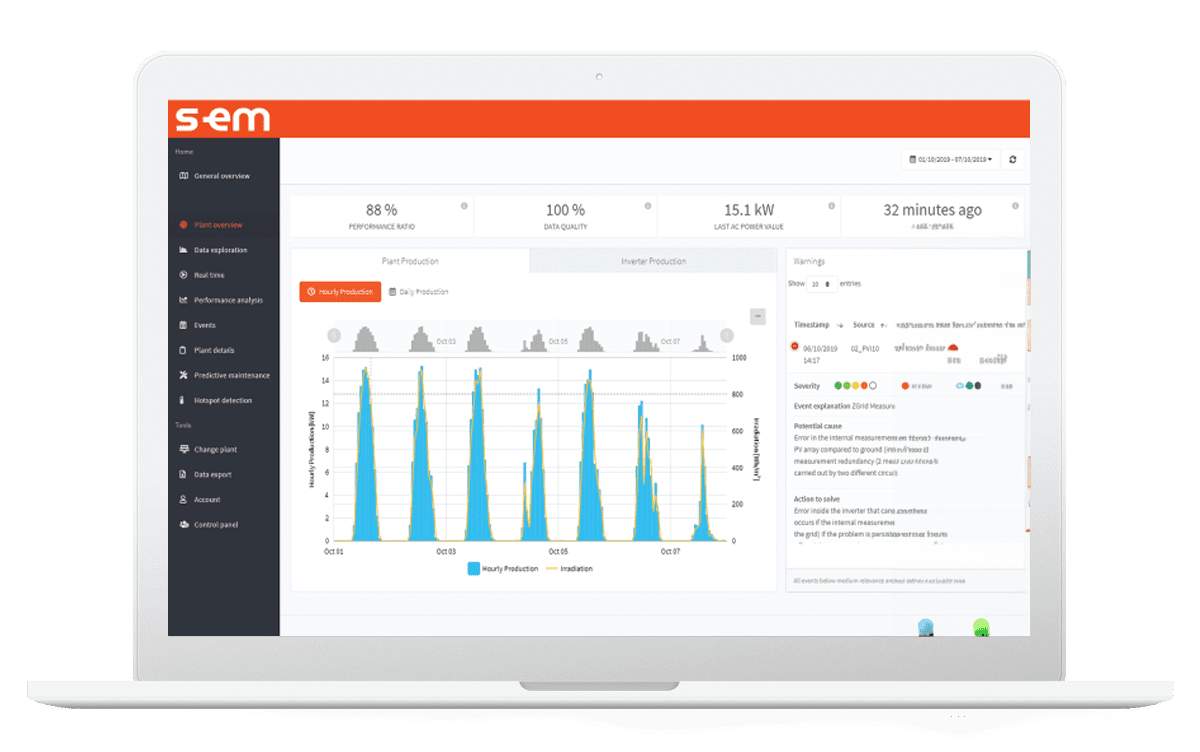

STANDARD MONITORING

Reliable and accurate management for single plant and portfolio

Our standard monitoring system is cloud-based platform which enables solar asset managers, solar asset owner and O&M operators to use all the value of PV plants data assets. The multi-level access provides different kind of information with reference to the different role of the user.

The platform follows the philosophy of business intelligence combined with advance analytics; easily analyse real-time status of solar plants, providing reliable and accurate values and KPIs for solar plant portfolio management.

FEATURES

- Centralized Management of PV portfolio

- Real-time underperformances alerts

- Automatic alerts configuration

- Automatic reporting

BENEFITS

- Increase of energy yield

- Reduction of plant downtime

- Reduction of energy losses

- Reduction of O&M costs

SOLUTION

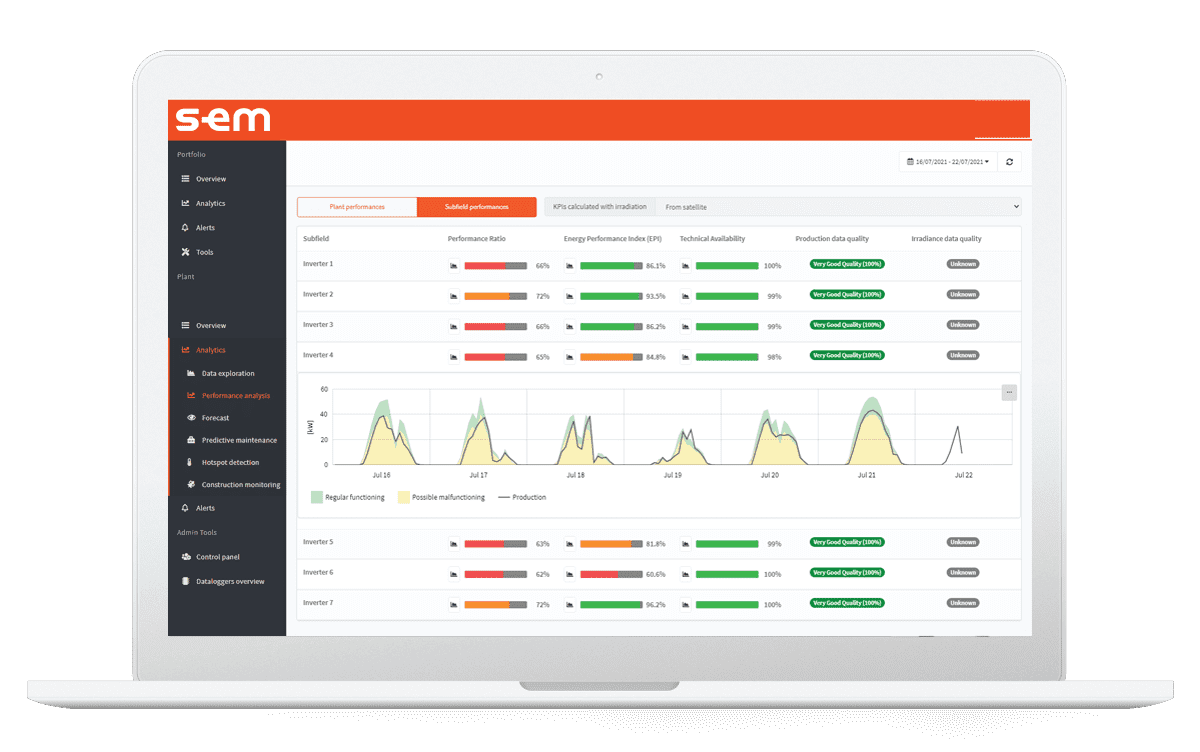

ADVANCED DIAGNOSTICS

Cutting-edge advanced analytics to monitor PV plants

Empowered by Artificial Intelligence, the advanced diagnostic system ensured reducing acknowledge time of faults giving exact information of components affected and precise identification of issues root cause (sharing, covering, thermal problem, faulty MPPT, inverter and string underperformance).

Data quality assessment is essential to ensure reliable analysis. i-EM data quality assessment models allow asset managers and O&M operators to get reliable KPIs.

FEATURES

- Automatic fault recognition

- Root cause identification

- Data quality assessment

- O&M calendar

BENEFITS

- Reduction of plant downtime

- Reduction of energy losses

- Optimization of energy production

- Optimization of assets’ financials

PLUG-INS

Enhance your system with additional functionalities and maximize versatility.

You can choose one of our packages or integrate these plugs in into your existing system, discovering all the benefits of customization and plant optimization.

PLUG-IN

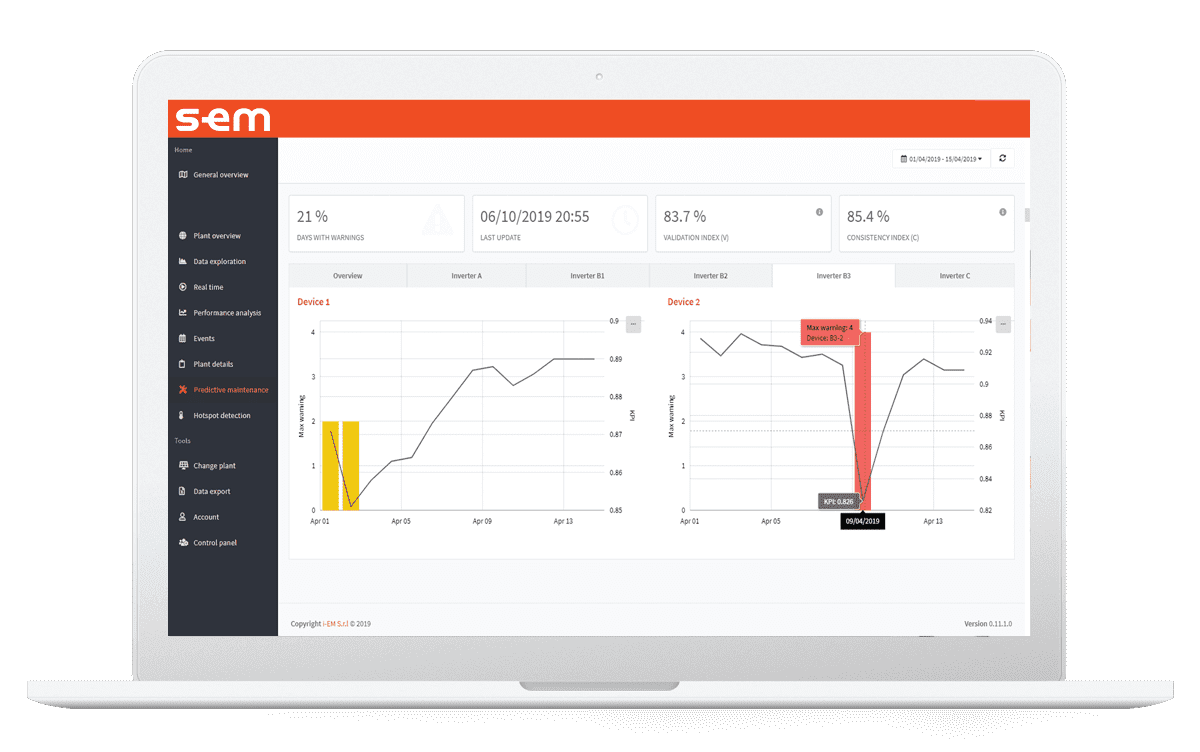

PREDICTIVE MAINTENANCE

Change your maintenance approach and give value to your data

This tool is able to predict (or easily detect) inverter faults status before they actually occur, allowing O&M operators and field technicians to take actions to avoid loss production period, increasing solar assets return on investment.

The system leverages an ensemble of best performing Machine Learning algorithms, to detect unhealthy status of PV plant inverters. The big data i-EM’s IT infrastructure to ingest and manipulate large and heterogeneous sets of data.

FEATURES

- Easy visualization of ML algorithms outcomes

- KPIs trend to understand warning evolution

- Identification of critical signals

- Analytics model self creation (Analytics as a Service)

BENEFITS

- Increase the lifetime of components

- Reduce plant downtime

- Reduce technical energy losses

- Optimization of O&M activities

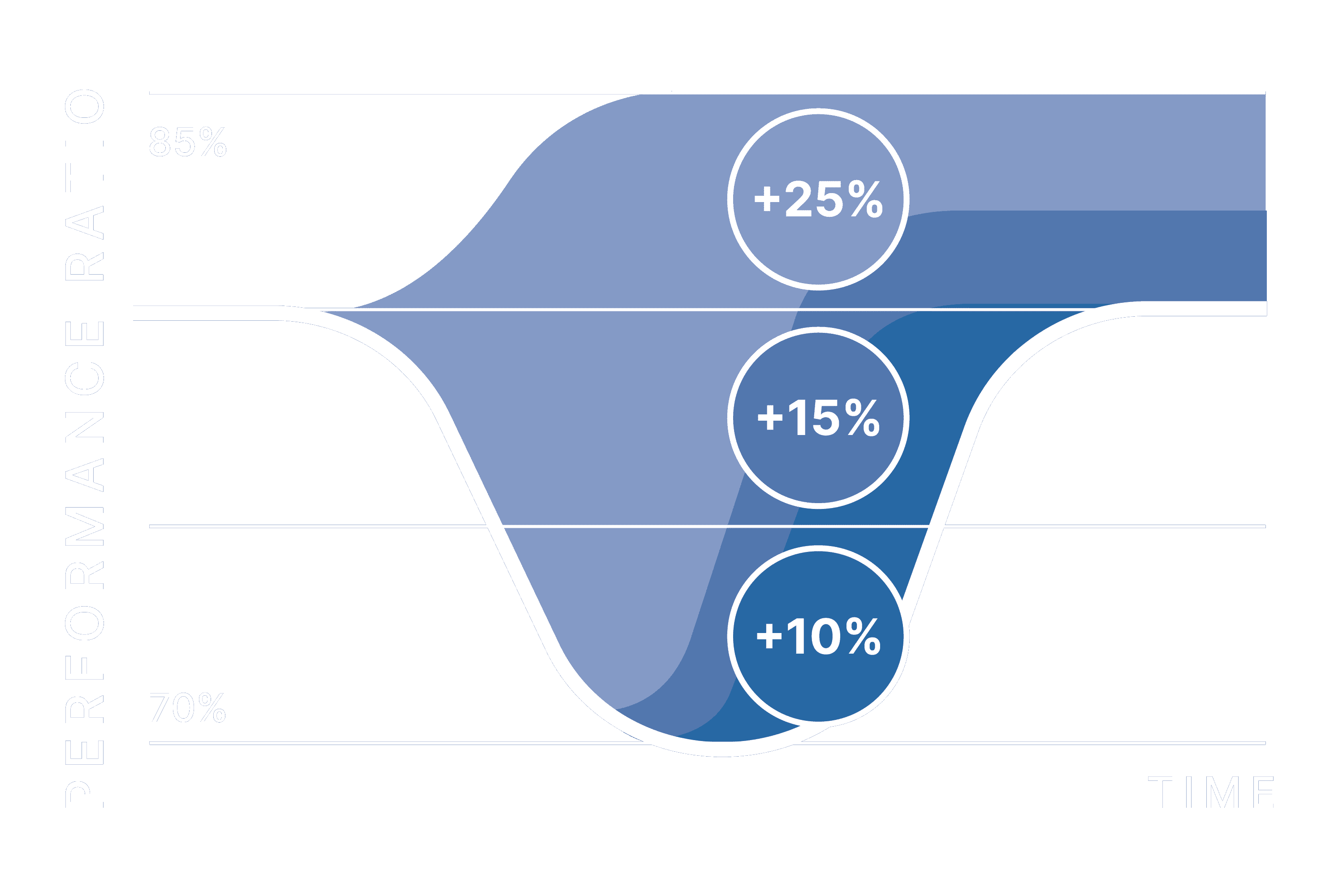

Boost your energy yield by 25% with this plug-in, combining machine learning and data-driven insights.

Enhance fault detection and optimize O&M activities.

PLUG-IN

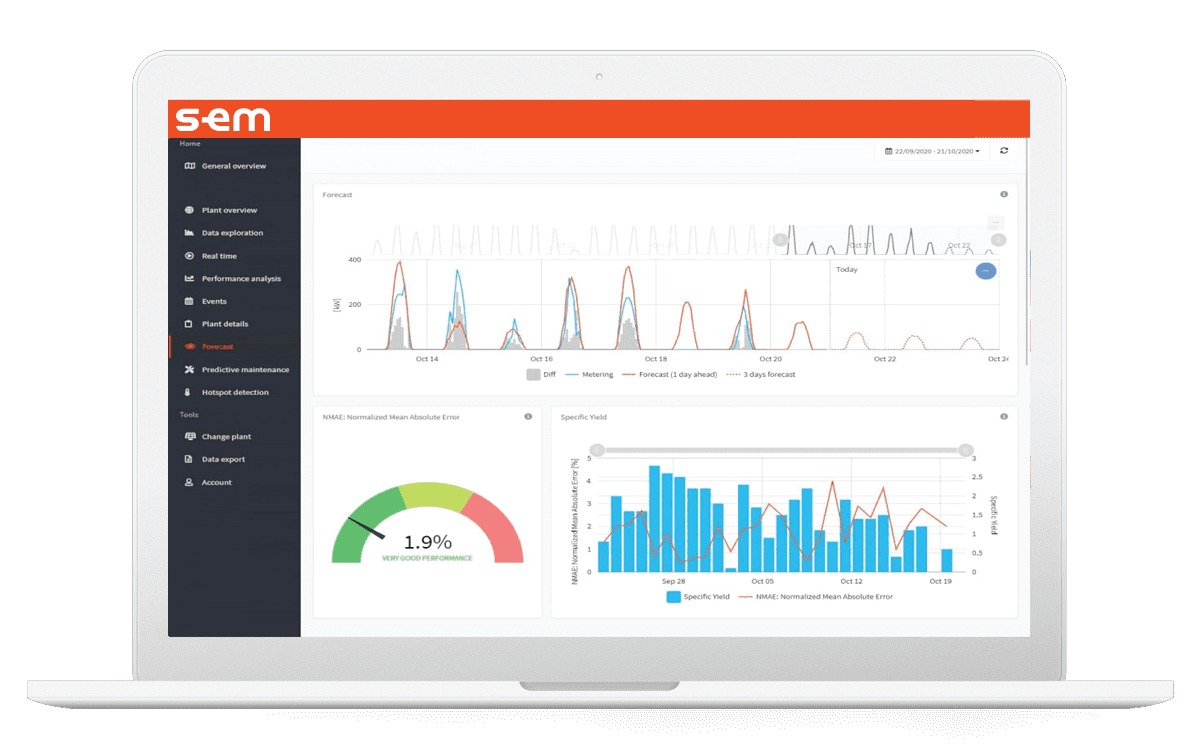

SOLAR PLANT POWER NOWCAST AND FORECAST

Get precise information from minutes to days ahead

Numeric weather prediction, satellite image and real-time measurement are used as inputs of an ensemble framework of Machine Learning algorithms in order to produce solar power forecasts from minutes to days ahead.

The service is highly flexible and reliable to ensure high-value benefits for energy producers, system operators and energy traders. Outputs can be delivered through any format and visualizes on a user friendly intelligent dashboard.

FEATURES

- Different time and spatial resolution

- Multiple daily updates

- Flexible output format and delivery area

- Plant, portfolio or regional solar power forecast

BENEFITS

- Improve plant management efficiency

- Reduce imbalance cost of penalties

- Ensure market and authorities requirements compliance.

PLUG-IN

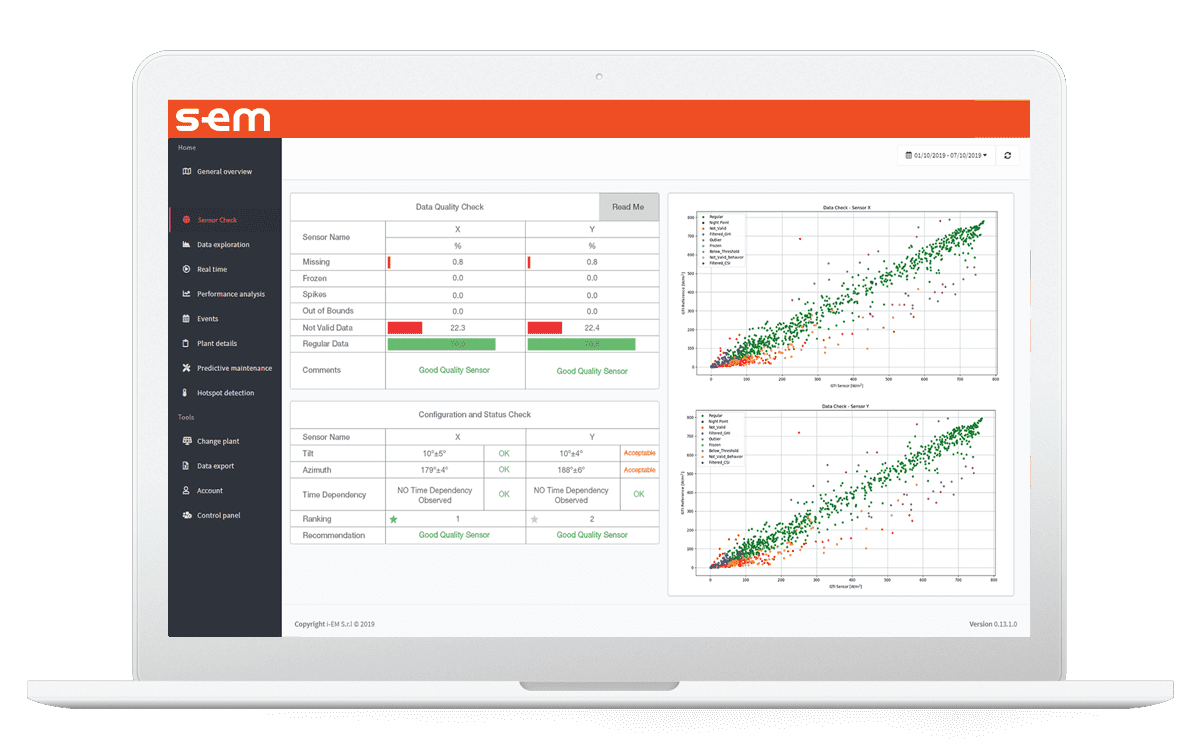

SOLAR SENSOR CHECK

Get accurate solar radiation measurement

Irradiance data gathered from satellite imagery are used for the automatic and real-time sensor condition based check-up, by detecting sensor failures and possible configuration issues.

Corrected irradiance sensor measurements dataset generation, exploiting satellite data (sensor statistical recalibration). Reliable and accurate long-term PV DC effects assessment, correlating the sensor measurements and satellite irradiance data.

FEATURES

- Automatic real-time sensor condition-based check-up

- Sensor statistical remote recalibration

- PV plant time-dependent drifting deviation assessment from nominal behaviour

BENEFITS

- Reliability in calculating photovoltaic plant performance (PR, EPI, etc…)

- Increases PV plant performance assessment reliability

- Save time and cost for O&M resources

- Advanced diagnostics of PV plants

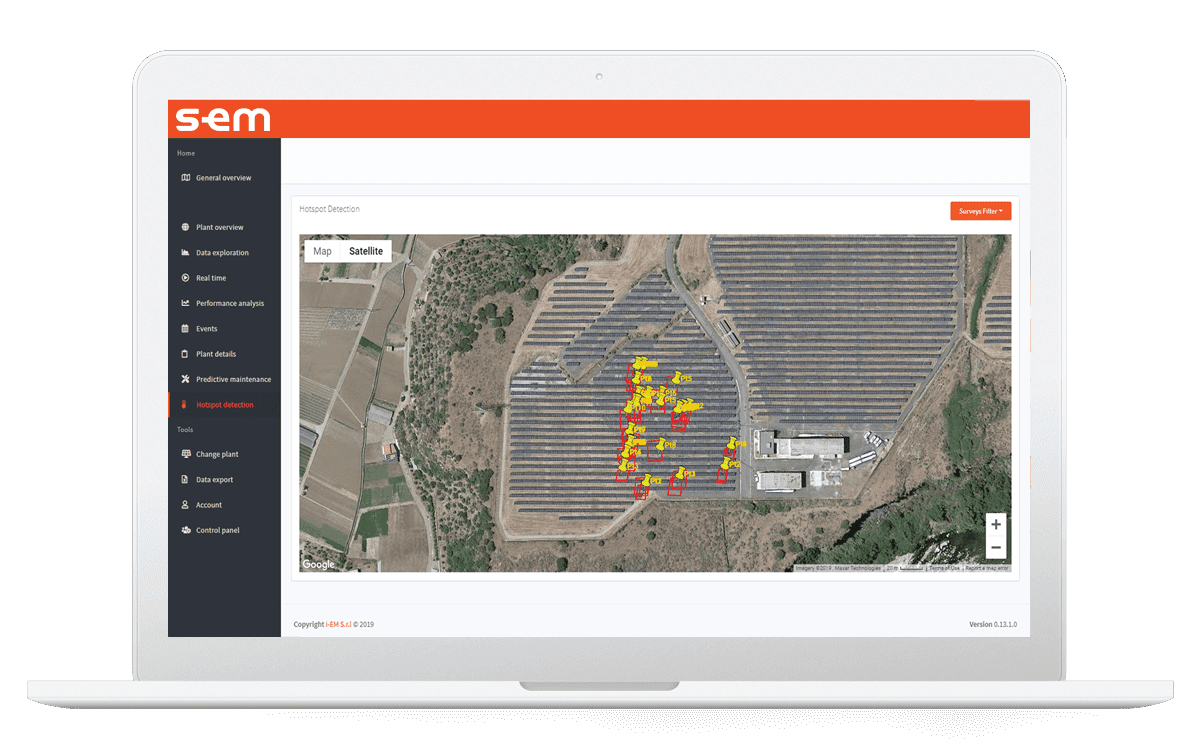

PLUG-IN

DRONE DATA MANAGEMENT

Hot Spot Detection and supervision of PV plant construction process

The combination of IR and visible image-video is used to automatically detect hotspots and other typical problems of rooftop or ground installation (dirt, delamination, etc.) and to provide accurate detection and count the number of panels, poles, trackers and cabin units.

All information is georeferenced and reported on the cloud-based platform to allow a clear overview of the photovoltaic plant, to support procurement stage in the acceptance phase and support O&M teams during plant operations.

FEATURES

- Detection and counting of panels, poles trackers and cabin unit

- Automatic detection of hot-spots

- User-friendly visualization of the information

- Georeferenced output

BENEFITS

- Optimize the acceptance process

- Optimize the O&M activities

- Improve plant performances

PLUG-IN

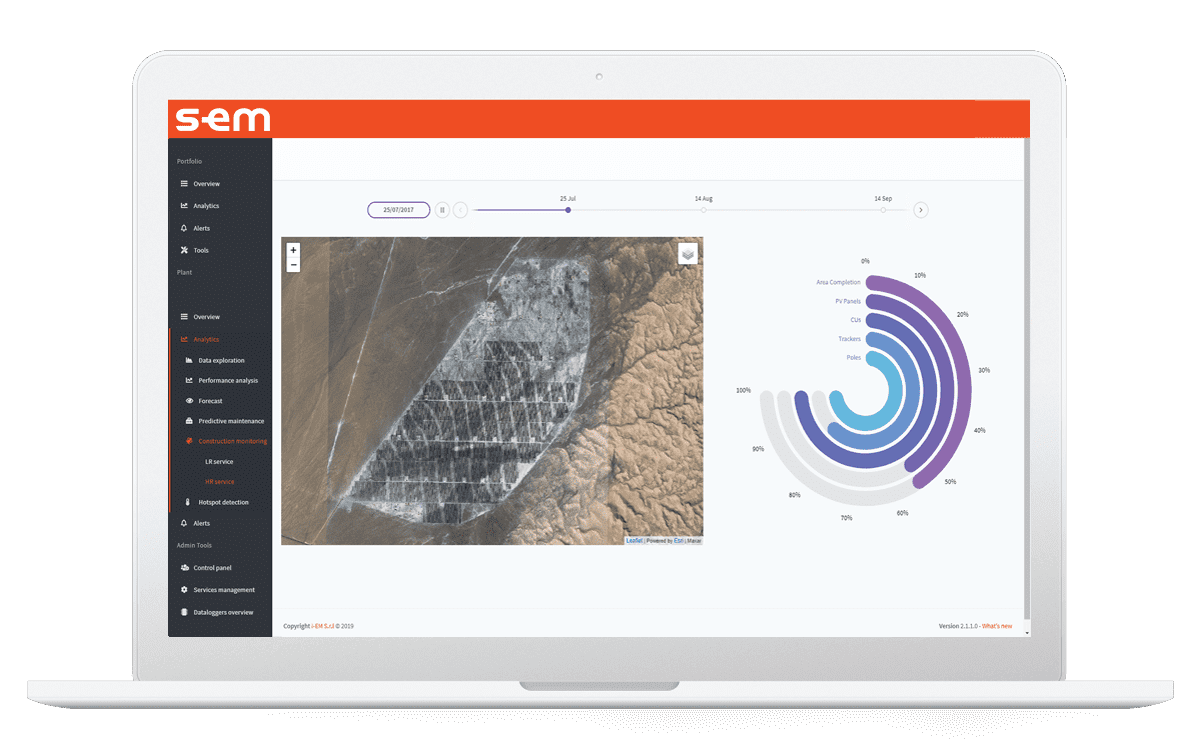

SATELLITE-BASED PLANT CONSTRUCTION MONITORING

Supervise remotely your PV plant construction process

Remote supervision of the solar construction progress. While LR (̴ 10m at ground) images aims the detection of the areas changed, the HR (0.3-0.9 meters at ground) service provides periodical information on construction process KPIs statistics for the main relevant building phases.

The image processing software exploits the combination of successive images supplying information about pole, trackers, PV panels trackers, PV panel and cabin units installed as well construction process percentage.

FEATURES

- Automatic processing of LR and HR images

- Area completion percentage and trend

- Detection of areas changed between two images acquisition

- User-friendly interactive visualization

BENEFITS

- Costs reduction for plant construction management

- Cost reduction in the management of plant documentation

- Monitoring of the work from remote

PLUG-IN

SELF-CONSUMPTION MANAGEMENT

Optimize the use of your solar power system

Nowcast and forecast PV plant production data are used in combination with real-time data to maximise the self-consumption, optimizing the usage of storage system and EV charging if present. This allow to define a strategy to minimize the energy exchanges with the grid during the current and the next day.

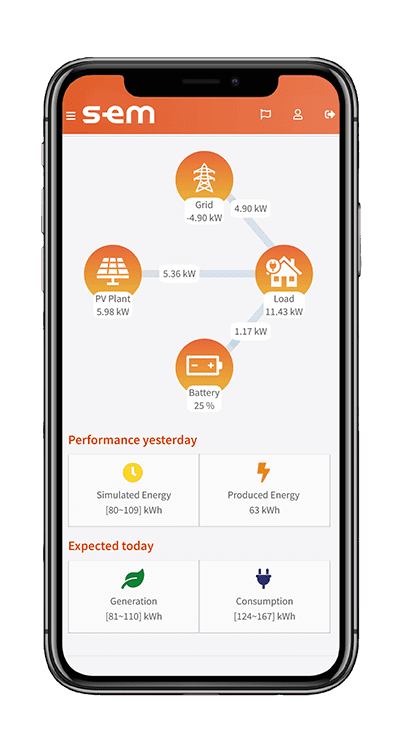

The mobile App allows the easy visualization of the values and parameters of the battery, such as the state of charge (SOC), the cycle of charging/disgorging, etc., providing advises for the best energy usage.

FEATURES

- Visualization of the energy flow

- Monitor and manage the system components behaviour

- Expected outcomes forecast based on usage options

- Advices on energy usage

BENEFITS

- Optimizing the usage of energy

- Minimize peak energy costs

- Reducing grid energy use

- Increasing battery life

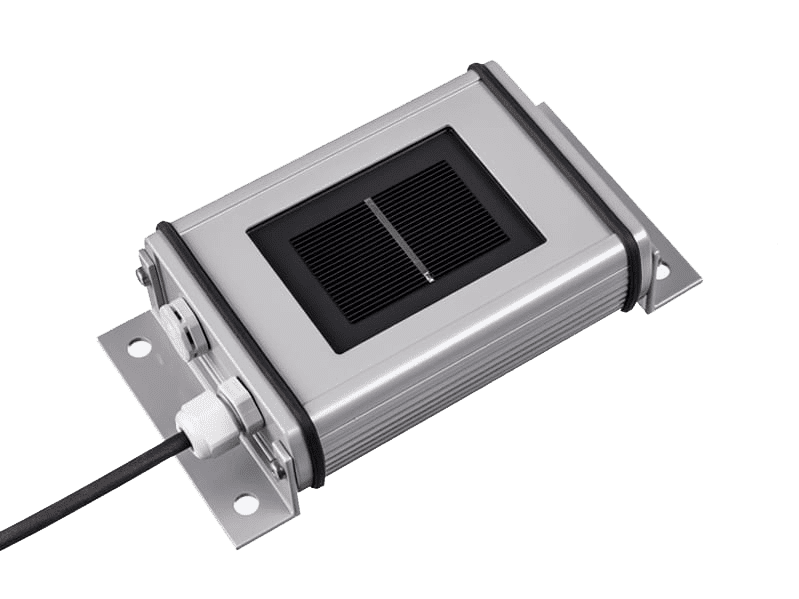

Silicon Solar Irradiance Sensor

Photovoltaic Reference Cells for PV Monitoring

i-EM is an official distributor of silicon sensor from Ingenieurbüro Mencke & Tegtmeyer GmbH since 2008. These photovoltaic reference cells offer an economical but robust and reliable solution for measuring solar irradiance levels, particularly for monitoring photovoltaic systems.

i-EM Data Acquisition System

- Long-lasting highly-robust system and complete Data Acquisition System for the acquisition of electrical parameters from inverters, strings and meteo-data in the field.

- Storage up to thousands of variables, and upload every 5-15 minutes on i-EM cloud.

Compatibility

- i-EM configures the datalogger with the standards of different inverters manufacturers.