Executive summary

KEY SOLUTION: h-EM | Predictive maintenance

Background

Predictive maintenance techniques applied to hydropower plants

In hydropower plants, planned periodic maintenance has been for a long time the main adopted maintenance method. Predictive maintenance methods can provide more efficient monitoring services, advanced fault prognosis, prediction of incipient faults and prescriptive maintenance tools. Benefits of this includes, among other things, preventing faults from occurring, avoiding unnecessary replacements of components, more efficient criteria for scheduled maintenance.

Challenge

Real-Time application of the predictive maintenance to an EGP plant

- rAcquire in real-time a large amount of data from the plant

- pProcess the data with advanced machine learning models aimed to failure anticipation

- rProvide synthetic and effective information to the operators through a web dashboard

- rModels auto-tuning from operators’ feedbacks

Solution

Failure anticipation on the EGP hydropower plant

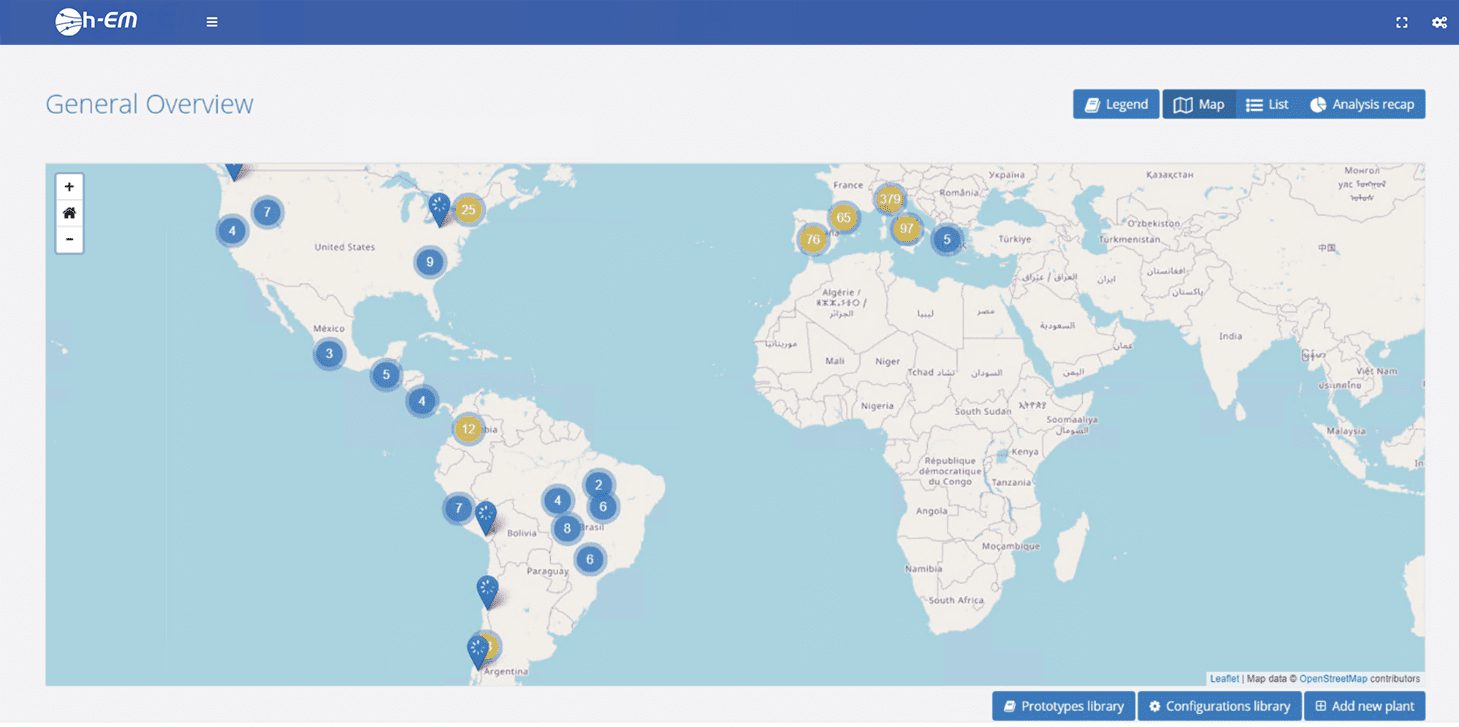

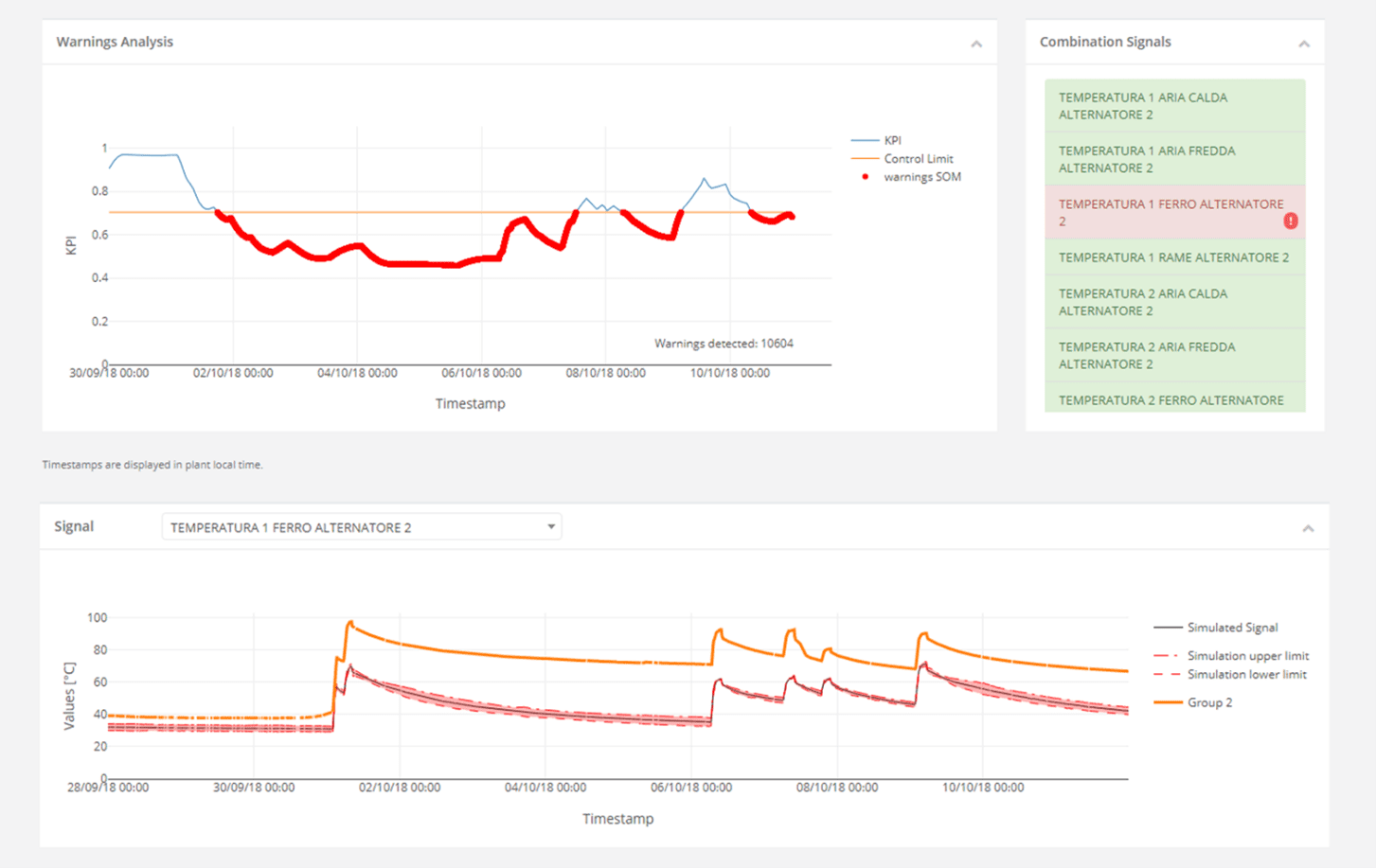

Our predictive maintenance solution proposes as output an interactive web platform (eMaintenance 2.0) where the operators can monitor the results coming from the data analytics models related to the functioning of the plant components and share comments between other colleagues. Here we propose a case study referred to the application of the solution to a pumped-storage power plant owned by EGP with a nominal power of 1000MW located in Italy in the Province of Caserta. The dataset available from this plant consists of about 720 analog signals. These signals are collected from several components such as penstocks, turbines, generators, and transformers. During the real-time phase of this case study, an anomalous behavior was reported by the model built to analyze the temperatures of a generator. At the time of the anomaly notification, temperatures values did not yet exceed the warning thresholds of the condition-monitoring systems already operative in the plant. After receiving the warning alert, the plant operators checked the component and confirmed the event as a relevant anomaly. They acknowledged that this was a serious problem, since a further degradation could have eventually led to the stop of the generation unit. For this reason, timely actions were taken: operators restored the nominal and correct behavior of the component. This approach has been successfully tested on several cases, and our solution is now active on more than 700 EGP hydro-power plants worldwide.

We received benefits from i-EM monitoring platform and from their statistical analysis and after a first application on 5 plants in Italy, we decided to expand this digitalization on other hydro plants worldwide.

Business impact

- NAnticipated notification of the anomaly prevented the stopping of the generation unit

- NThe saved costs related to the predictive notification were estimated in the range between 25 k€ and 100 k€

- NThanks to the provided information, the anomaly was restored with a reduced time spent to search the faulty component

- NScalable solution, easily applicable to a large fleet of power plants

Interested in this solution?

Our team will be happy to look at your specific needs and help you reach your goals in Energy Management.